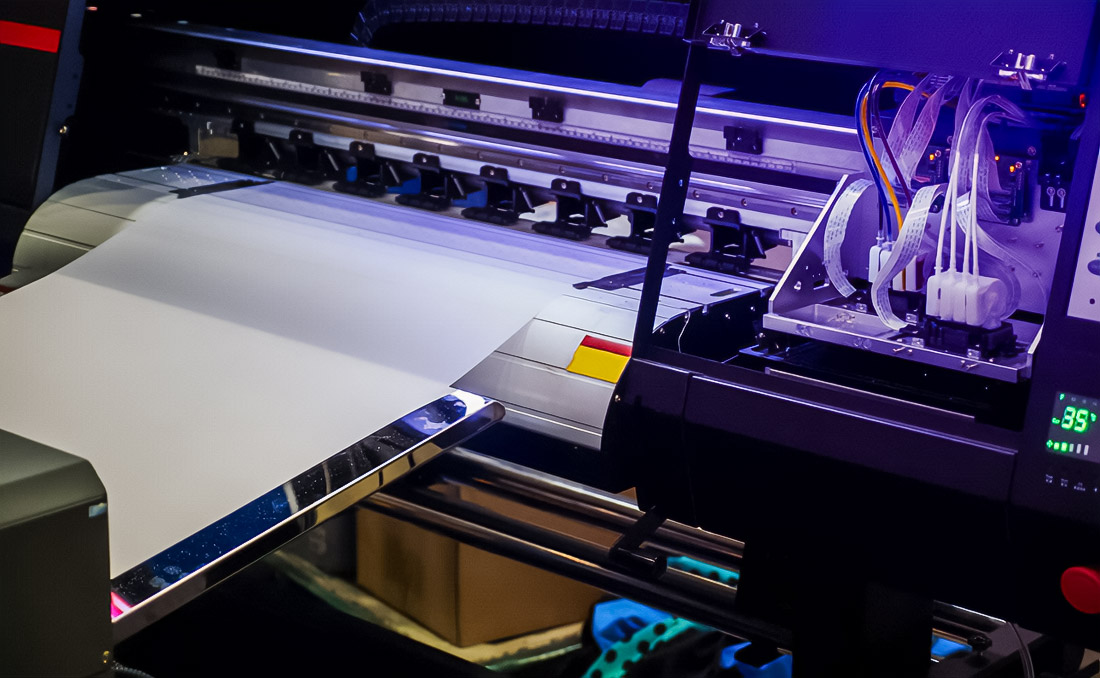

Three things are important in merch.The picture should be bright. The impression must be kept after dozens of washes. Production cannot slow down before the start of the event. DTFtransfers solve all three tasks. Direct to Film printing provides high resolution, a soft-touch layer and stable color. You only need heat press, film, adhesive powder and the correct modes. Temperature 300-325°F, average pressure, time 10-15 seconds. At 320°F and the right peel, the result is crisp, elastic, and durable.

Where the DTF Is Expanded to the Maximum

Organizers of concerts, sports games, and exhibitions value speed. The actual time frame includes 24 hours for production, and if you order before 12 PM EST, it can be shipped on the same day. The capacity reaches 15,000 square feet per day, which covers the needs of large events. There is no minimum quantity. This is convenient when you need to test a design on a small batch, and then instantly switch to bulk orders. DTF works with cotton, polyester, nylon and blends. It fits perfectly on T-shirts, hoodies, baseball caps, bags and light uniforms. Personalization is important in sports equipment. Game numbers are read at a height of 10-12 inches on the back, 8-10 on the chest. Logos are often placed in the range of 6-8 inches, surnames are in 2-3 inches font. These dimensions maintain the visibility and balance of the composition.

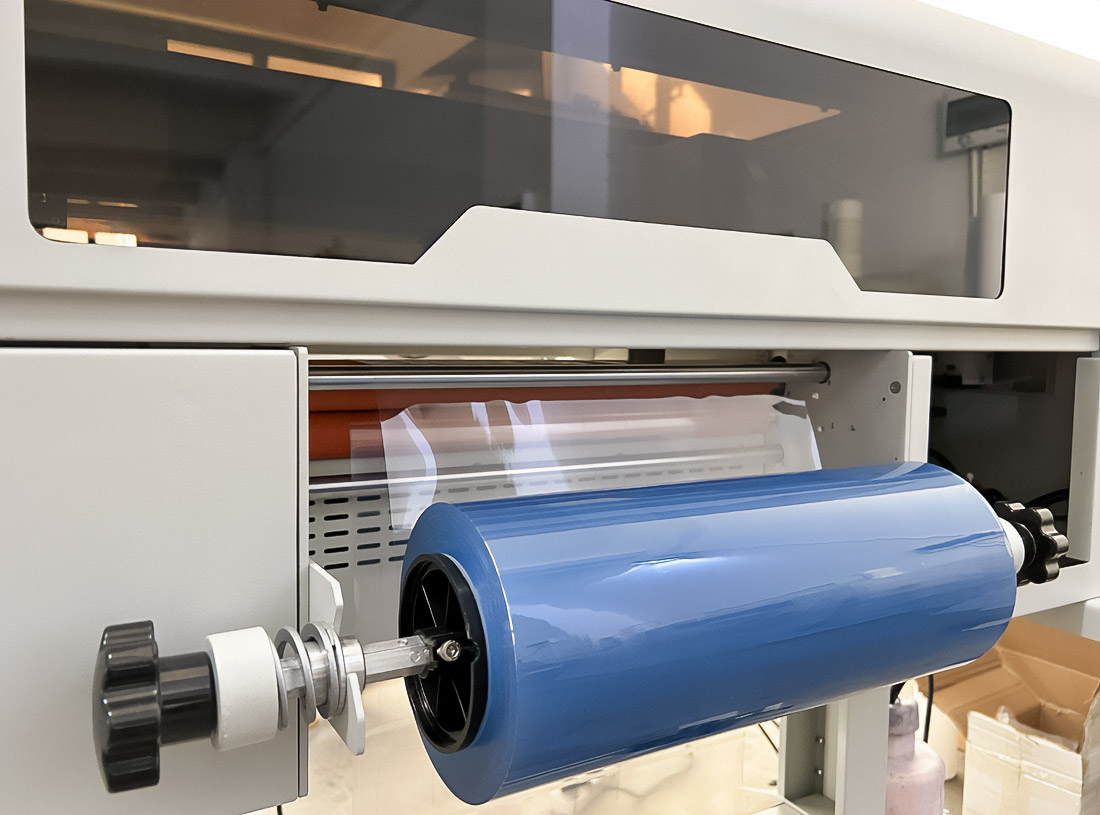

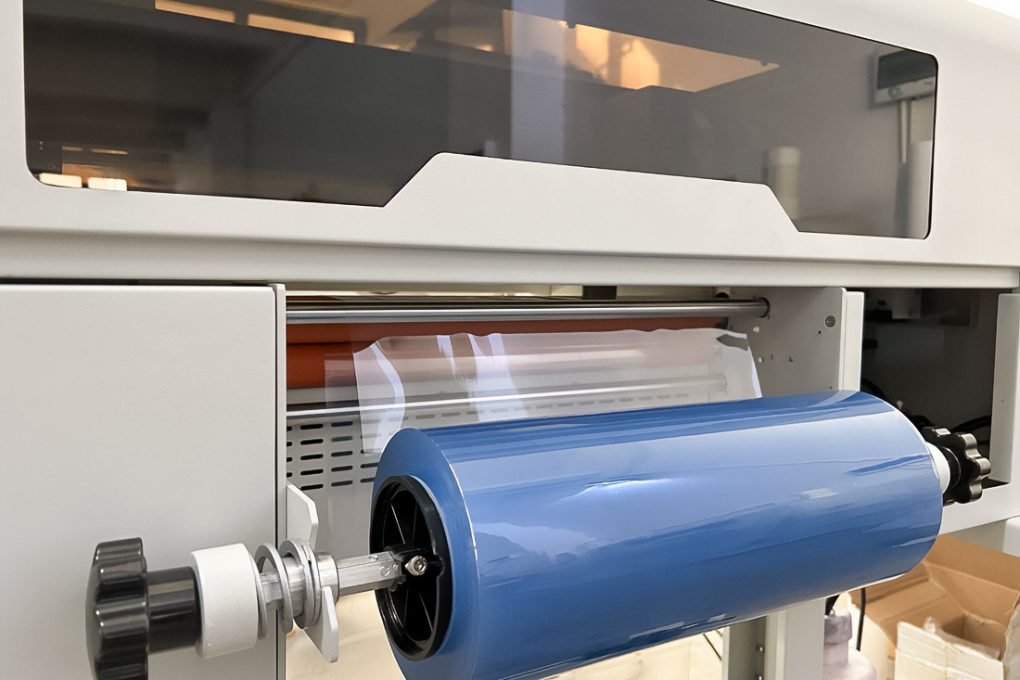

Technology and Transfer Options

The process is simple.Film printing, powder application, heat and pressure fixation. The white backing enhances the contrast on dark fabrics. Raster graphics must have at least 300 DPI. It’s easier to keep fine lines and gradients in a vector. Coating options expand the tasks. Hot peel saves seconds in high-performance lines, but requires a more precise mode. Cold peel forgives the mistakes of the press and is suitable for beginners. Glitter DTF adds sparkle to fan merch and holiday series. Thermochromic changes the visual effect when heated. UV DTF works on hard surfaces. Bottles, glasses, cases and boxes also receive stable graphics. Ready-to-press sheets speed up the flow. Gang sheet layout reduces the cost. The size range is wide. From 1×1 inches to 22.5×25 feet, and gang rolls go up to 30 feet. It is convenient for sets of numbers, logos and names on one sheet. High-volume studios often rely on DTF printing supplies in the USA to maintain consistent quality and reliable results across multiple production lines.

Economics, Care and Quality

Pricing is transparent. A print costs about $0.03 per square inch or $3.50 per square foot. A 22.5×24-inch standard sheet is priced at about $14. Discounts are included for volumes starting at 400 square feet. Free shipping is activated after $200. This approach removes the barrier of entry and allows you to scale without unnecessary expenses for the preparation of matrices. The application takes 10-15 seconds, which gives a high rate of order collection right before the event. The durability indicators are confident. The impression can withstand 50 or more washes if the regime is followed. The water temperature can reach up to 140°F. To extend the service life, wash inside out, avoid air conditioning, and dry at low heat. For additional strength, it is allowed to reheat for about 5 seconds after the film is peeled off. Peel can be done warm or cold, it depends on the type of media. Store the sheets in a dry, cool place, in airtight bags, away from light. The optimal application period is 3-6 months, but under the right conditions, the film retains its properties longer.As a result, DTF transfers provide predictable quality, vibrant colors, high detail, and flexible circulation. Reduced adjustment time, no clipping, compatibility with performance fabrics and moisture-wicking materials maintain a stable fit of the layer. In practice, this means being ready for deadlines, clear merch, and satisfied fans.

Baseball fan, hustler, DJ, Bauhaus fan and identity designer. Producing at the crossroads of design and purpose to give life to your brand. I sometimes make random things with friends.